Resources

21 Design Tips

Looking at your magnetic design requirements and not sure where to start?

These 21 Design tips will help to get you started

Need more help? Give us a call

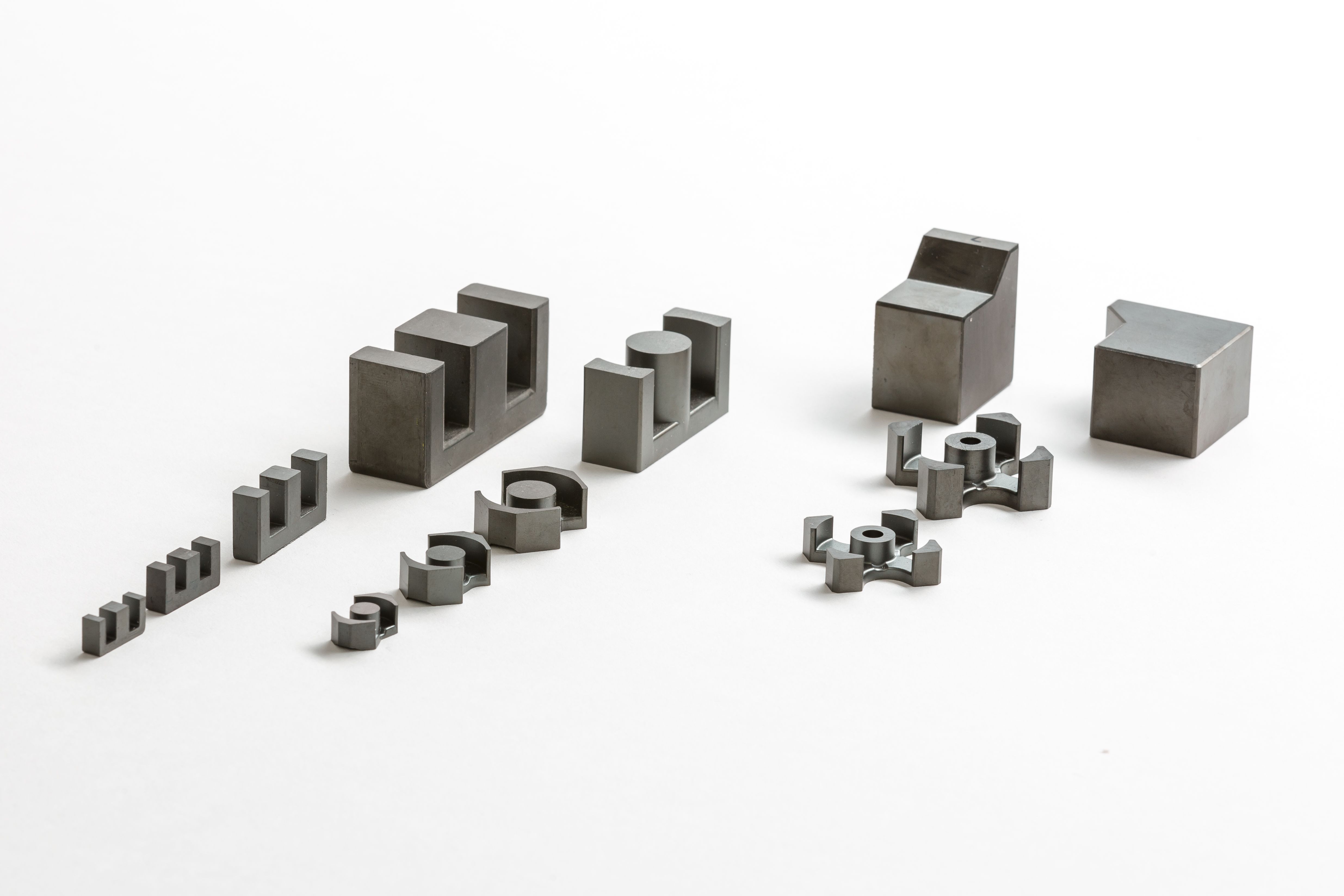

Choosing Transformer Cores for different SMPS topologies

The selection of the magnetic components to be used in a Switch Mode Power Supply (SMPS) design is the most important element of that process. During this, understanding the topologies of SMPS’ is crucial as the designer must consider the trade-offs between them. This article will give you an overview of these tradeoffs.

Using core VA ratings to determine transformer dimensions

I am writing this to share my views and experience in the design of magnetics (transformers and inductors), something in which I have been involved for most of my professional life. As in any design process, there are a number of critical parameters that must be met in order to achieve “success” and they are all intricately interrelated.