I am writing this to share my views and experience in the design of magnetics (transformers and inductors), something in which I have been involved for most of my professional life. As in any design process, there are a number of critical parameters that must be met in order to achieve “success” and they are all intricately interrelated. It is the interrelationship of these parameters, and the trade-offs between them, which I will be discussing here in order to help clarify your options and the impact of these choices on the magnetic components you design.

I will begin by determining the physical size of a transformer based on a specified power level required.

Why is this important? Because the magnetics are generally the most expensive, heavy and bulky components on any PCB, and space is usually at a premium. Therefore you need to insure you are able to fit the magnetics in their allocated space for the power level required for your design. Much of my time at Marque Magnetics has been dedicated to fixing the “allocated space versus required power and performance” issue for companies who did not do this simple check before designing their board and/or enclosure.

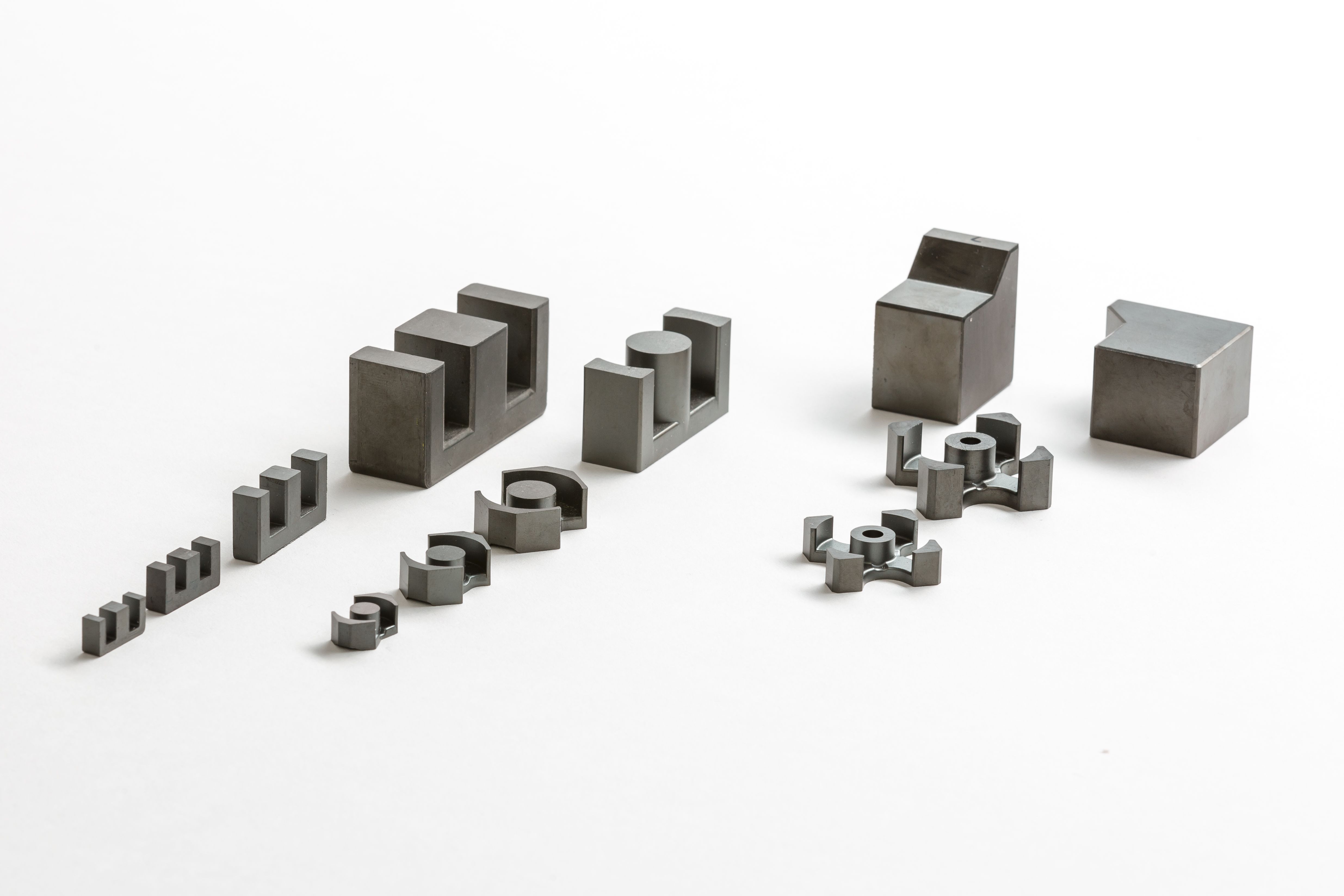

The size of the transformer is dependent on the size of its core. It’s dimensions are quite variable as they are available in multiple geometries and materials with different electrical and magnetic properties. The most common are C-cores, E-cores, Pot cores, and Toroids, all of which come is many grades of steel, ferrite, iron powder, and alloys.

The size and the shape of a core, represented as “area product” ( Ap) , defines its power-handling ability and therefore the ultimate size of the transformer. The Ap is the product of the core window (Wa) and the core cross-sectional areas (Ac).There is no need to calculate Ap during your core selection process as the manufacturers publish them, in VA, for their products. Once you have then identified a number of cores, which could be of different materials and geometries, that meet your power requirement, you can look these up on supplier websites or manuals for their dimensions to find which best fit the space allocated on your PCB or product.

Below are two charts which allow you to quickly and easily choose from popular ferrite cores or steel laminations by power levels. You can also go to the USEFUL TOOLS button beside this blog and use our Sizing Ap as it quickly identifies cores and also gives you the overall dimensions of the finished transformers. Have a go.

Once you have determined what cores sizes you are going to use, you can begin the actual magnetic design. I will go into this in my next post.

Steel Lamination Cores (based on 50/60Hz) using H14 material

Power range (W) | Lamination type | |

|---|---|---|

Imperial | Metric | |

<5 | 306; 212 | EI28; EI35, EI41 |

5-10 | 212 | EI41; EI48 |

10-20 | 212; 130; 120 | EI48, EI54 |

20-50 | 120; 279; 43 | EI54, EI57; EI66 |

50-100 | 279; 43; 174; | EI66, EI76 |

100-200 | 174; 173 | EI96; EI114; |

200-500 | 173; 180 | EI114; EI133 |

500-1000 | 180; P; | EI133, EI150 |

>1000 | Q; S | EI171 |

For the detailed magnetic core material characteristics, please see the table9 on page 154 in “Magnetics core selection for transformers and inductors” (2nd edition, C. Mclyman)

Related Resources

Choosing Transformer Cores for different SMPS topologies

The selection of the magnetic components to be used in a Switch Mode Power Supply (SMPS) design is the most important element of that process. During this, understanding the topologies of SMPS’ is crucial as the designer must consider the trade-offs between them. This article will give you an overview of these tradeoffs.

Using core VA ratings to determine transformer dimensions

I am writing this to share my views and experience in the design of magnetics (transformers and inductors), something in which I have been involved for most of my professional life. As in any design process, there are a number of critical parameters that must be met in order to achieve “success” and they are all intricately interrelated.